|

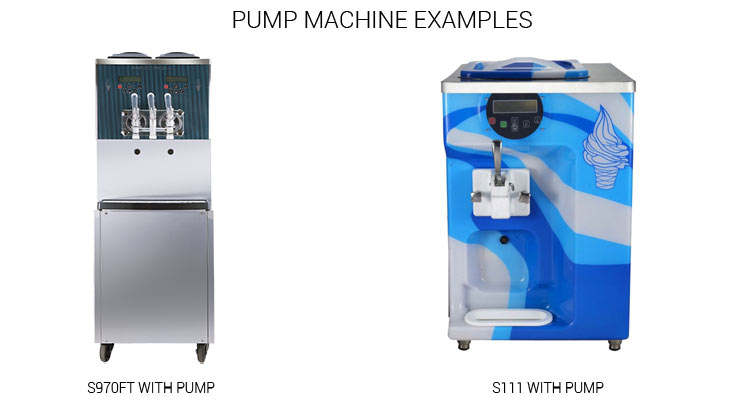

When purchasing or renting a soft serve machine for your ice cream shop, restaurant, or other business, you will have to decide whether or not you want a pump or gravity-fed machine. It is important to know the difference! Depending on your situation, one may work better for your needs than the other. So what are the differences? The main difference is how your mix is fed into the cylinder. Gravity Fed Machines - With these the mix is fed into the cylinder using... Gravity! It is fed through a tube down into the freezing cylinder. It does this with a fixed air ratio of about 30%. Meaning that you will have a 30% ice cream overrun (30% extra ice cream compared to the mix. Pump Fed Machines - These have a pump in the hopper which feeds the mix into the freezing cylinder so that you can control the amount of air you want. This way you can control the amount of overrun you have in each batch, oftentimes by up to 80%. Even though upon first glance of overrun production, it may appear that a pump machine is superior, this is not always the case. Each type has advantages and disadvantages. Advantages of gravity-fed machines: • More affordable • Easier to use • Easier to clean • Easier to maintain • Fewer Parts • Ice cream has a stronger more intense flavor Disadvantages of Gravity Fed Machines • Less ice cream overrun • Ice cream is not as soft or creamy • Slower at making ice cream Advantages of pump machines

• Ice cream is creamier and has more texture • Larger amounts of overrun • Makes ice cream faster and more efficiently • Better for high-demand shops Disadvantages of pump machines • More expensive • Harder to clean • More difficult to use • More parts in use Your decision really boils down to two main things. If your sales volume is high and you need to make a larger amount of ice cream, then you want a pump machine. If you are a small business that wants to add some extra revenue with soft serve, go with a gravity machine. PASMO offers both gravity and pump-fed machines so that you can get the best fit for your business. If you would like to order a top-of-the-line PASMO soft serve machine, please call us at 1-844-52-PASMO You can also view our machines Here.

0 Comments

Is a frozen drink machine worth it for your business?

A better question might be... Do you want to increase profitability and decrease production times? The answer to that is surely yes! In 2021 the frozen drink market was valued at well over $50 million and is growing at an annual growth rate of 6% per year. Frozen drinks are VERY popular with all age groups, especially Gen Z and Millennials. In fact, according to a recent study, almost 70% of Gen Z and 50% of Millennials drink frozen drinks. Costs and Profitability While a frozen drink machine may initially set you back a few thousand dollars, the ROI per machine is high and profitability is achieved quickly. On average frozen drinks have a profit margin of 65-70% and depending on the capacity of your machine and how many drinks you serve per day... You can become profitable in no time. The PASMO 728 is a high-capacity machine that is always ready and requires ZERO waiting in between drinks. It's the ultimate machine for efficiency and quick profitability. In general, frozen beverage machines are very low maintenance, parts last for a long time, and replacing parts is a simple process. Combine all of this with a high demand for frozen drinks and you've got another source of reliable income for your restaurant, bar, or dessert shop. Ease and Convenience Why do so many people like frozen beverages? Think of it like this: You aren't selling a frozen drink... You are selling Instant refreshing relief from a hot summer day. In this day and age people (especially the younger generation) are looking for instant gratification. They are less likely to order a frozen drink if they know someone has to spend 10 minutes making it. But the minute a customer spots the familiar window filled with churning slush in a drink machine... They are ready to purchase. Extremely Versatile It's a common misconception that frozen beverage machines are "margarita machines" but this just is not the case. Yes, they can produce delicious margaritas on demand, instantly. But they can also do SO much more! Smoothies, milkshakes, granita, slushies, a multitude of alcoholic drinks, non-alcoholic mocktails, and more. The PASMO 728 allows for quick and easy changing of flavors and types of drinks so that you can offer whatever you would like without the hassle. Just switch the consistency settings to whatever type of beverage you are serving and viola, you are ready to serve. If adding another exciting revenue stream to your store sounds like a good idea, visit our website to learn more and get started. The preventative maintenance schedule on soft serve and shake freezers requires all rubber seals and necessary bearings to be replaced every three months. These components come in a convenient tune-up kit that can be purchased through the parts department.

By replacing these wear items you will establish the “Preventative Maintenance Program”. This simply means, by replacing the items subjected to normal daily wear on a scheduled basis you can prevent costly maintenance charges and the cost of more expensive spare parts charges on your freezer. For example, damaged rubber seals can cause damage to the beater motor, compressor, and any other expensive electrical components. The cost of the damaged component combined with the service charge for component installation is what can multiply the expected yearly maintenance cost. The problem is then compounded by a poor yield due to product loss, freezer down time, and loss of sales. The required replacement of the freezing cylinder scraper blades is included in the “Preventative Maintenance Program”. The suggested replacement schedule for metal scrapers blades is every six months (four months for plastic blades), Using scraper blades beyond their expected life will cause excessive running time of the freezer. The adverse affect caused by increasing the running time is often recognized by poor product quality, low yield, decreased capacity, and increased utility cost. In the mechanical production of ice cream and other frozen dessert products, ice cream mix is combined with air in order to produce a tasty and profitable final product. For soft serve ice cream, the air content can vary from 0% to 60% of the total volume of the final product. The amount of air allowed in the mix alters the taste of the final product. Product with low quantities of air have a heavy, icy taste and feel and product with a higher air content tastes creamier, has a smoother consistency and is generally considered "lighter". The optimal quantity of air vs mix is determined by ingredients and individual taste. In general, the preferred air content is between 30% and 45% of volume. This is called "Over Run"

Soft serve ice cream mix is kept preserved at the ideal temperature in a tank (PASMO uses a single stainless steel tank with no welds for reliability and safety) which is refrigerated and controlled by a thermostat. The mix remains in the tank until it is delivered by means of gravity or a gear pump into the freezing chamber where it is intimately mixed with the targeted quantity of air, stirred, and quickly frozen to obtain a state of "soft serve". An important reason for a machine to have an air pump is to increase the volume of the ice cream by adding more air than is traditionally available using the built in "Carburetor" to the mix. This affects the machine in two ways: First, it reduces the amount of mix in a given volume of soft serve, which increases the qty of final product the machine is able to freeze per hour; and, secondly, it decreases the density of the soft serve, and thus increases ice cream “softness” creating a sensation that it is less cold to the palate. Under ideal working condition, the pump delivers a constant, perfect supply of liquid mix and gas (usually air) to the freezing chamber in a predetermined ratio between air and liquid mix. However, the "Carburetor" may not work under expected ideal condition due to imperfect mechanical assembly it may become clogged; the ratio between air and mix may be decreased, the volume of soft serve produced per container of mix may be decreased; the taste of final product may be changed; the production performance of the machine may be compromised. Therefore there is a need to provide a solution to overcome the aforementioned problems to improve the efficiency of the soft serve machines - The Air Pump. I like to give the example of weight versus profit. Most, if not all, modern Self Serve Frozen Yogurt stores require a "more dense" final product to help add weight to the cup and therefore more profit at the scale. Conversely, stores that sell final product on a per cup basis do not need a dense or heavy product, and the use of air both makes the product lighter, fluffier and more volume is produced per case of mix providing more profit. Think of Costco which sells Frozen Yogurt by the cup versus your favorite frozen yogurt store. PASMO America offers an Air pump on most of our models. Call for more information, pricing, or to place an order. |

AuthorPASMO AMERICA is disrupting the Soft Serve Machine Industry. To find out how call us Archives

August 2022

CategoriesCategories |

Contact Us:1-844-52-PASMO [email protected]

Corporate Offices:

23961 Craftsman Road, Ste E Calabasas, CA 91302 Test Kitchen, USA ServiceLine,

Parts Distribution Warehouse 800 E. 64th Ave., Unit 4, Denver, CO 80229 844-52-PASMO |

Informational LinksTerms & Conditions

|

View Us On

|

RSS Feed

RSS Feed